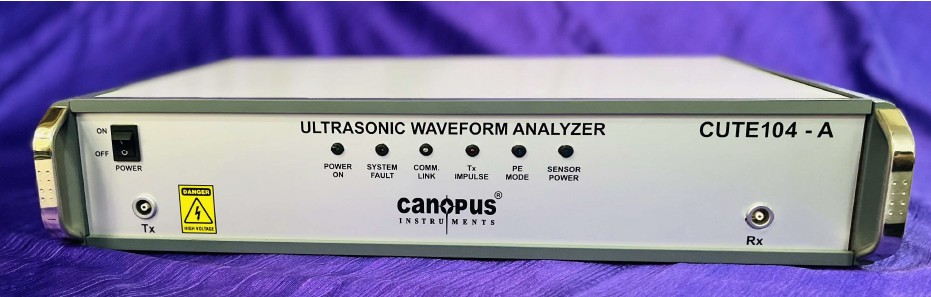

Ultrasonic Flaw Detector

CUTE104A is a high performance, bench top system useful for Generation of Ultrasonic waves & Analysis of the received wave behaviour in Non-destructive testing (NDT) of materials. Use of CUTE104A is aimed at low frequency Ultrasonic Testing applications (<500KHz) required for testing of non-homogenous materials & layered composites. CUTE104A system supports Transmit/Receive (T/R), Pulse/Echo (P/E), & Pitch Catch modes commonly used for Ultrasonic testing.

High Voltage (1000Vpp) Tone Burst signal of set frequency can be generated to drive the Transmitting (Tx) transducer. This is extremely useful in enhancing the performance of the Tx transducer when it is pulsed at its resonance frequency. Programmable High Gain (0 – +60dB) receiver amplifier is provided, with added option of interfacing Receiver (Rx) Transducers having In-Built amplifier (Gain +26dB). Besides providing high gain, this provides advantage of reduced noise and enables use of long receiver cables (50m) with the use of 50 Ohm impedance matched co-axial cables. Operation of the CUTE104A system requires connection to an external computer system, which runs the software utility CUTE 104A-Connect provided with the instrument system.